Ideal for critical applications in railway, electrical, aerospace, and industrial sectors.

Safety, Precision, and Efficiency in Industrial Additive Manufacturing

Halogen-free flame-retardant material, now with 60% reusability for efficient additive manufacturing. Complies with UL94 V0 and EN45545-2 for critical applications.

Optimize Your Production with 60% Reusability in PA12 FR

Productivity and Sustainability with 60% Powder Reuse

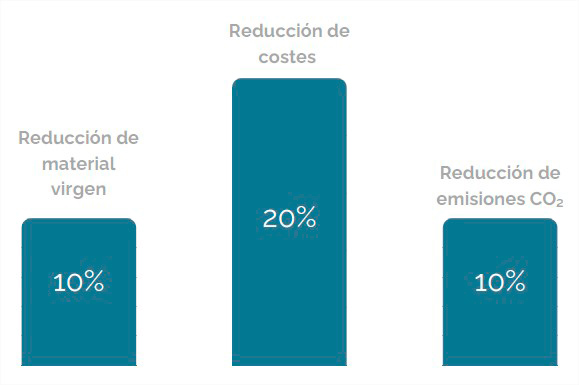

- Lower Cost per Part: Reduced reliance on virgin powder per build lowers variable production costs.

- Consistent Properties: The 60% reuse rate maintains strength, isotropy, and surface finish, ensuring batch-to-batch quality.

- Less Waste: Minimizes scrap in continuous production or medium series, aligned with industrial sustainability targets.

- Sustainable Manufacturing: The polymer is produced using biomethane and renewable sources, contributing to a lower carbon footprint from origin.

Developed by Evonik and HP, the new PA12 FR enables a 60/40 powder reuse ratio-setting a new benchmark for industrial-grade additive manufacturing.

Direct Impact of the New 60/40 Reuse Ratio

Perfect for cost-efficient and sustainable production in regulated sectors such as railway, electrical, and aerospace.

Technical Properties of PA12 FR

Consistent Performance in Demanding Environments

PA12 FR combines stable mechanical performance, thermal resistance, and flame retardancy compliant with stringent standards.

Mechanical Properties

| Property | XY Average | Z Average | Test Method |

|---|---|---|---|

| Tensile Strength (MPa) | 46 | 46 | ASTM D638 |

| Tensile Modulus (MPa) | 2580 | 2540 | ASTM D638 |

| Elongation at Yield (%) | 3,8 | 3,6 | ASTM D638 |

| Elongation at Break (%) | 4,7 | 4 | ASTM D638 |

| Impact Strength (kJ/m²) | 2,8 | 2,7 | ASTM D256 |

| Density (g/cm³) | 1,13 | - | ASTM D792 |

Dimensional Tolerances

| Tolerances at Cpk= 1,33 | 0 - 30 mm | 30 - 50 mm | 50 - 80 mm |

|---|---|---|---|

| XY | ± 0,20 mm | ± 0,25 mm | ± 0,30 mm |

| Z | ± 0,42 mm | ± 0,50 mm | ± 0,60 mm |

| Tolerances at Cpk= 1,00 | 0 - 30 mm | 30 - 50 mm | 50 - 80 mm |

| XY | ± 0,15 mm | ± 0,18 mm | ± 0,22 mm |

| Z | ± 0,34 mm | ± 0,40 mm | ± 0,47 mm |

Advanced Flame-Retardant Performance

Certified Safety for Critical Sectors

Formulated to meet the highest fire safety standards, PA12 FR is halogen-free and validated through demanding flammability tests. It is ideal for components in railway, electrical, aerospace, medical, and industrial environments.

Su composición sin halógenos y su rendimiento probado en ensayos de inflamabilidad lo convierten en la solución ideal para componentes en entornos ferroviarios, eléctricos, aeroespaciales, de salud e industriales.

Flammability Ratings

| Standard | Classification | Thickness / Condition |

|---|---|---|

| UL94 | Vo | ≥2,5 mm |

| V2 (TBD) | ||

| HB | ≥1 mm | |

| UL 746A | HAI: PLC o | 2,5 mm |

| HWI: PLC o | ||

| UL 746B | CTI: 400V | |

| RTI | 65°C | |

| IEC 60695-2-12 | GWFI | Available upon request |

| Ball Pressure | Available upon request | |

| Dielectric Strength | Available upon request |

Railway Standard EN45545-2

| Requirement | Classification |

|---|---|

| R22 | HL2 (1,4 - 10 mm) |

| R23 | HL2 (1,4 - 10 mm) |

| R24 | HL2 (1,4 - 10 mm) |

| R26 (UL94 Vo) | 2,5 mm |

Real Applications with PA12 FR

Optimize Your Critical Components

Industrial companies are already leveraging PA12 FR to reduce costs, shorten lead times, and meet strict regulatory requirements. Discover how additive manufacturing transforms functional parts:

Protective Shields

- 50% cost reduction

- 93% lead time reduction

Designed by Bronymec

Relay Blades

- Previously CNC-machined in metal

- Consolidated from 9 parts to 2

Designed by Bronymec

Fluid Systems

- Formerly made from machined stainless steel

- 20 × lighter

Data courtesy of Markem-Imaje

Pioneering Experience in PA12 FR

Bronymec was selected by HP as the first beta tester in Europe for PA12 FR, working with the material since September 2024.

Since then, we’ve developed solutions for highly regulated sectors such as:

- ? Railway

- ⚡ Electrical & Electronics

- ? Industrial

- ✈️ Aerospace

- ? Medical Devices

We offer not only the production of PA12 FR parts but also expert technical support to:

- Optimize designs for additive manufacturing.

- Ensure compliance with UL94, EN45545-2, and IEC standards.

- Reduce costs and lead times in critical applications.

CONTACT

Technical advice for PA12 FR

We make our extensive experience available to our customers when selecting the right polymer for each application. We have simulation tools, where we have included the characterization of our range of polymers, in order to obtain accurate and reliable results.